联系人:杨经理

电话:0510-85386636

手机:18001518665

尚蒙科技无锡有限公司

地址:江苏省无锡市新吴区菱湖大道228号天安智慧城A1-602

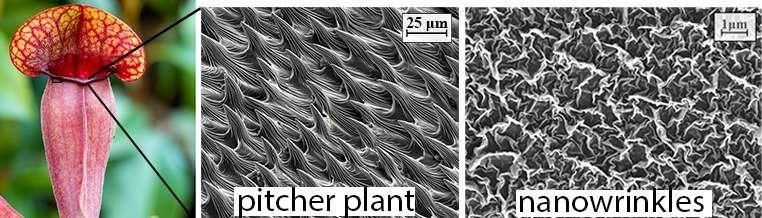

船体的海洋微生物污染是非常重要的航海和海洋捕捞中关心的问题。水生物可以在船只停泊的短期内污染水下船体表面,导致船只损坏。目前主要的方法是通过在其船只表面喷涂可以释放有害物质的涂料,达到去除或者防止水生物污染的目的。但同时也会破坏海洋微生物的生存环境。最近,澳大利亚的悉尼大学的纳米研究所得科学家们开发了一种纳米皱纹得涂层,能够无污染的通过物理杀菌过程防止船体表面的海洋污染。结果发表在ACS Applied Materials & Interfaces.上。

Biofouling - the build-up of damaging biological material - is a huge economic issue, costing the aquaculture and shipping industries billions of dollars a year in maintenance and extra fuel usage. It is estimated that the increased drag on ship hulls due to biofouling costs the shipping industry in Australia $320 million a year。

Since the banning of the toxic anti-fouling agent tributyltin, the need for new non-toxic methods to stop marine biofouling has been pressing.

Leader of the research team, Associate Professor Chiara Neto, said: "We are keen to understand how these surfaces work and also push the boundaries of their application, especially for energy efficiency. Slippery coatings are expected to be drag-reducing, which means that objects, such as ships, could move through water with much less energy required."

The new materials were tested tied to shark netting in Sydney's Watson Bay, showing that the nanomaterials were efficient at resisting biofouling in a marine environment.

The research has been published in ACS Applied Materials & Interfaces.

The new coating uses 'nanowrinkles' inspired by the carnivorous Nepenthes pitcher plant. The plant traps a layer of water on the tiny structures around the rim of its opening. This creates a slippery layer causing insects to aquaplane on the surface, before they slip into the pitcher where they are digested.

Nanostructures utilise materials engineered at the scale of billionths of a metre - 100,000 times smaller than the width of a human hair. Associate Professor Neto's group at Sydney Nano is developing nanoscale materials for future development in industry.

Biofouling can occur on any surface that is wet for a long period of time, for example aquaculture nets, marine sensors and cameras, and ship hulls. The slippery surface developed by the Neto group stops the initial adhesion of bacteria, inhibiting the formation of a biofilm from which larger marine fouling organisms can grow.

The interdisciplinary University of Sydney team included biofouling expert Professor Truis Smith-Palmer of St Francis Xavier University in Nova Scotia, Canada, who was on sabbatical visit to the Neto group for a year, partially funded by the Faculty of Science scheme for visiting women.

In the lab, the slippery surfaces resisted almost all fouling from a common species of marine bacteria, while control Teflon samples without the lubricating layer were completely fouled. Not satisfied with testing the surfaces under highly controlled lab conditions with only one type of bacteria the team also tested the surfaces in the ocean, with the help of marine biologist Professor Ross Coleman.

Test surfaces were attached to swimming nets at Watsons Bay baths in Sydney Harbour for a period of seven weeks. In the much harsher marine environment, the slippery surfaces were still very efficient at resisting fouling.

The antifouling coatings are mouldable and transparent, making their application ideal for underwater cameras and sensors.

![]() Explore further: Researchers show laser-induced graphene kills bacteria, resists biofouling

Explore further: Researchers show laser-induced graphene kills bacteria, resists biofouling

More information: Cameron S. Ware et al, Marine Antifouling Behavior of Lubricant-Infused Nanowrinkled Polymeric Surfaces, ACS Applied Materials & Interfaces (2017). DOI: 10.1021/acsami.7b14736

上一条: 快如闪电 科学家研发新型DNA纳米机器人

地址:江苏省无锡市新吴区菱湖大道228号天安智慧城A1-602 :0510-85386636 传真:0510-85384339 电子邮箱:info@solmontech.com

: